Steel is a versatile material that can be molded into any shape and hence matches up with any building design preferences. Also it is highly durable. And all these and more factors make steel structures popular in the construction world today especially in commercial sectors such as warehouses, shopping malls, hospitals and so on. And many people are also considering it for their residential building construction as well.

Decades back wooden and mud houses were in fashion which resulted in exploitation of trees and woods as building materials. And this led to deforestation to a great extent that again helped in enhancing global warming! But with time people became concerned for saving the environment and today steel structures are being mostly used as building materials. Steel structure buildings offer a better quality and a lot more luxury than that of a building built of wood!

There are a wide variety of advantages steel structure buildings have that are making these framed buildings popular among people of every stratum. Usually, red iron is being used for structural frames and light gauge is used for non-structural frames. Structural steel not only works great for skyscrapers but can also be used for various industrial and commercial buildings such as shopping malls, hospitals, schools and likewise because of its good attributes. This material is extremely versatile and is used during different stages of construction that includes roofing, flooring for joists and framing. And when properly designed steel structure buildings became energy efficient as well.Nowadays, many people also prefer steel structures for their residential purpose by remodeling their current building.

Let us check out what all are the advantages of steel structures that make them such a hit in today’s construction world.

Easy Installation

As the steel structures are accurately engineered, they fit part by part simultaneously in a great manner. This helps in reducing the need of getting exceptional fasteners. It also needs fewer workers for completion of the entire construction process. Steel structure buildings do not need retaining and cutting of heavy planks which means the construction process is faster regardless of the size of the building.

Cost Effectiveness

Again as the steel structures/frames are slashed with accuracy during the manufacturing process, it greatly minimizes the wastage as it could be the case when timber is used for construction. Also, by lessening the number of workers for the construction process, the labor costs get minimized to a great extent.

Superior in Quality

Superiority in the quality can be adjudged because the steel structures unlike wooden buildings do not age and get worse over time. With a steel structure building you need not have to worry for any feeble spots. Also steel is corrosion resistant and steady that gives you a peace of mind that even with climatic changes your building will be safe and stand still.

Safe and Resistant

When safety is concerned, steel is far better and superior to wood due to its blaze resistance. Steel structures are also resistant to bugs, termite damages, rodents, fungi and mold. Another factor that makes steel structure buildings safer is that you need not have to worry about any chemical treatments for its quality maintenance. Your valuables are much safer in steel structure buildings that they would be in a wooden building!

Durability

Unlike other building materials, steel are extremely strong and will not divide, rotate, rot, splinter, chink or buckle. The best part of steel structures is that although these are strong but are not heavy making it simpler to produce and handle and even lift for construction purposes. And the durability of steel makes it a low maintenance structure.

Author Information:

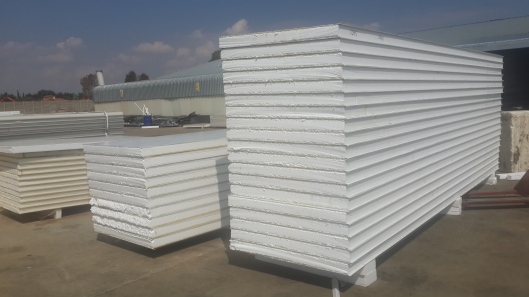

This article is written by Afripanel, providing well-engineered prefabricated steel structures for various commercial as well as residential projects in South Africa. For more details visit https://www.afripanels.co.za/steel-structure-buildings/